The above figures are representative values and not guaranteed values. *Microtrack MT3300EXⅡ

Surface Treatment of Various Powders

In addition to ST fillers for various rubbers and plastics, we also perform inorganic filler surface treatments such as the following. Depending on the type of polymer and the intended use, the type and amount of treatment agent can be changed arbitrarily. We provide small-scale prototypes and samples using lab machines. Please feel free to contact us regarding any request that you may have.

| Processing details |

Purpose |

Filler name |

Application |

Treatment agent / effect |

| Surface treatment |

Mechanical properties

Oil and water resistance

Improved dispersibility |

Hard clay |

Seal rubber, electric wire |

Silane coupling agent |

| Calcined clay |

Various rubbers and engineering plastics |

| Anhydrous silica |

Various rubbers and engineering plastics |

| Aluminum hydroxide |

Polyolefin flame retardant |

| Magnesium hydroxide |

Polyolefin flame retardant |

| Improved water repellency |

Calcium carbonate |

Polyolefin, etc. |

Silicon oil |

| Superior filling, dispersion |

Clay, talc |

Polyolefin, etc. |

Organic titanate |

Surface Treatment of Various Powders

Silane coupling agents are generally expressed by the following chemical structure formulas.

X: Hydrolyzable group directly bonded to silicon atom (methoxy group, ethoxy group, etc.)

Y: Organic functional group that reacts with organic matrix (amino group, vinyl group, etc.)

A silane coupling agent is a compound made from a hydrolyzable group that can bind to an inorganic filler and an organic functional group that can bind to an organic matrix, both in one molecule. The silane coupling agent firmly bonds both the inorganic filler and the organic matrix.

In general, the following effects can be obtained by using a silane coupling agent.

- 1.Improved mechanical and electrical characteristics

- 2.Improved dispersibility of inorganic filler

- 3.High content of inorganic filler

- 4.Improved heat resistance and flame resistance

- 5.Improved water resistance

- 6.Improved formability

Currently, various inorganic fillers for composite materials have been developed. However, silane coupling agents are not effective for all of these. The effect varies depending on the surface condition of the inorganic filler. .

Other Powder Processing

In addition to the surface treatment of powders, we also perform the following mixing, crushing, and classification processes upon request. We provide small-scale prototypes and samples using lab machines. Please feel free to contact us regarding any request that you may have.

| Processing details |

Purpose |

Filler name |

Application |

Treatment agent / effect |

| Mixture |

Precision mixing |

Mica, talc |

Cosmetic raw materials |

Fine particle polymers |

| Mica, talc |

Dusting powder |

Third component added |

| Liquid pulverization |

Anhydrous silica |

Engineering plastic |

Silicon oil |

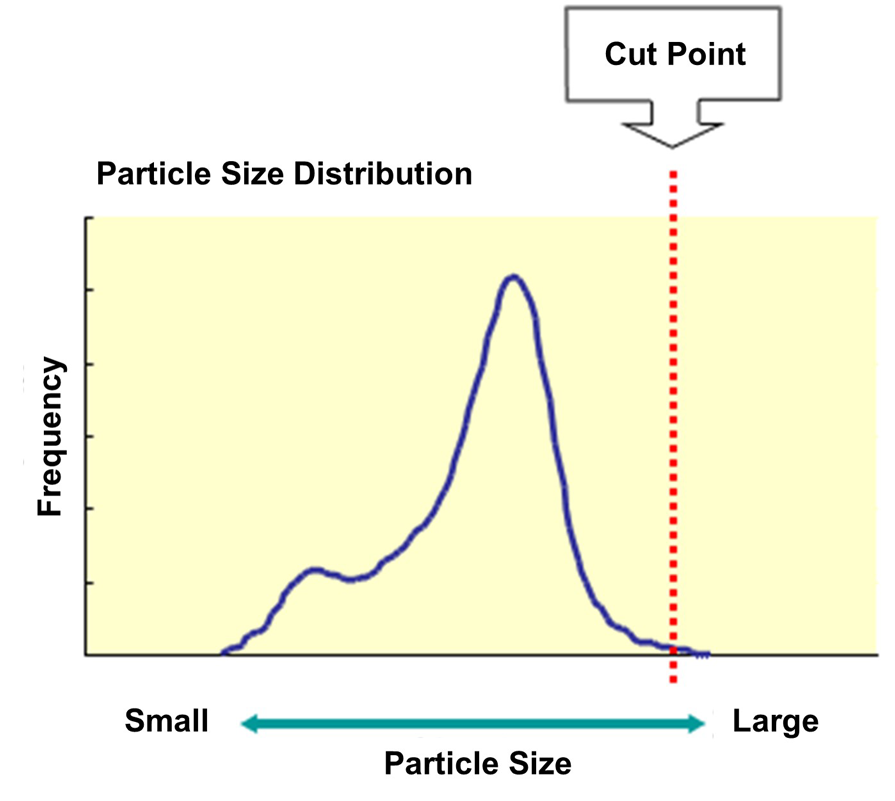

| Crushing / classification |

Removal of coarse particles and foreign matter |

Hard clay |

Special rubber seal materials |

Reduction of product defect rate |

| Diatomaceous earth |

| Calcined clay |

Rubber for electronic parts |

| Adjustment of top size |

Hard clay |

Precision rubber rolls |

| Calcined clay |

Thin rubber sheets |

*Removal of coarse particles

The 45 μm sieve residue is greatly reduced and the particles become smaller.

Example. CROWNCLAY 0.025%

↓

ST-CROWN 0.0025%

*Removal of foreign matter

Removes iron powder, paper waste, thread waste, wood waste, plastic pieces, etc.

By removing coarse particles from fillers, surface defects can be eliminated and the product defect rate can be significantly reduced.